Graphite

INDUSTRIAL GRAPHITE & PYROLYTIC GRAPHITE

Graphite for industrial use is a synthetic material created from crystalline carbon. Through the manufacturing process, graphite is extruded into blocks, rounds or other shapes. Graphite can be produced to deliver specific qualities, such as hardness, porosity or thermal conductivity, among others, by altering how the material is manufactured.

Graphite delivers very high thermal resistance and thermal conductivity, making it ideal for applications that experience quick heating such as automobile brake pads. This high tolerance for heat, along with being nearly non-porous, means you will find graphite in a number of casting and refractory uses, such as crucibles and ladle coatings.

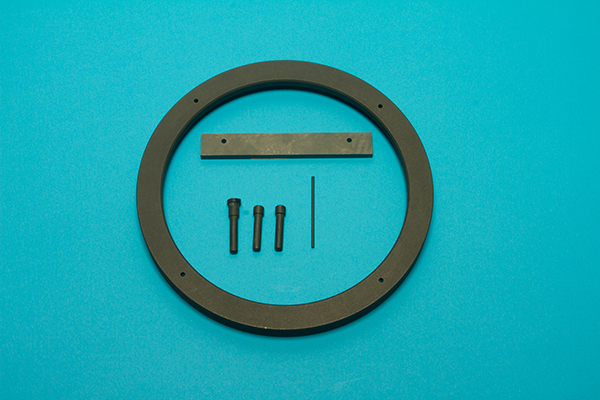

Applied Ceramics has the experience necessary to precisely machine graphite into a number of shapes and forms to exacting tolerances. Care is needed in machining graphite as the material is different than metal as it does not bend when cut, but can produce minute particles and fissures. Our skilled technicians are well versed in CNC graphite machining techniques to accurately cut graphite into the products customers demand. We can drill, mill, saw or grind graphite to your specifications.

ACI is also a supplier of pyrolytic graphite, a unique form of graphite that is a high level of diamagnetism – the ability to repel or be repelled by a magnetic field.

Contact an experienced Applied Ceramics professional to discuss your graphite application, learn more about the graphite machining process, and work together to design and deliver the parts you need to your desired specifications.

APPLICATIONS

- Electrical components such as motor brushes and heat sinks

- Industrial castings and molds for continuous casting applications

- Carbon fiber products such as automotive and aerospace parts

- Refractory and foundry equipment such as furnace linings

MAIN PROPERTIES

- High thermal resistance & good thermal conductivity

- Resistant to acidic or base solutions

- Near-zero porosity

- High compressive strength

- Low friction and self-lubricating

-

Graphite

Properties Units Graphite MECHANICAL Density g/cm3 1.57-1.88 Color – black Water Absorption % 0.5-3.0 Flexural Strength MPa@room temp.(R.T.) 50 Compressive Strength MPa@R.T. 96 Hardness GPa 8.5 THERMAL Coefficient of Linear Thermal Expansion 1E-6/°C

(»25°C to Ј1000°C)8.39 Thermal Conductivity W/m°K@R.T. 95.6 Specific Heat cal/g°C@R.T. 0.16-0.38 Thermal Shock Resistance D T(°C) 200-250 Maximum Use Temperature °C – ELECTRICAL Volume Resistivity Ohm. cm@R.T. 0.45-1.00×10-3 Dielectric Constant 1MHz@R.T. –