CERAMIC MACHINING & OTHER FINE MATERIAL MACHINING SERVICES

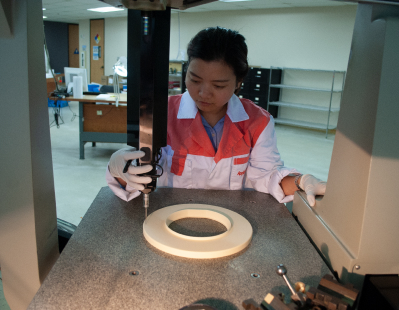

Ceramic Machining Services & More

Applied Ceramics supplies and fabricates custom ceramics, quartz, silicon, and sapphire parts for the semiconductor, solar, fuel cell, oil drilling and nuclear industries.

We specialize in offering precise, reliable, and high-quality ceramic machining solutions all while providing you with great value - no matter the application.

CERAMIC MANUFACTURING RELIABILITY

In the world of getting innovative products to market, the pressures for time efficiency is intense and unrelenting. Applied Ceramics’ excellent track record of reliability in delivering high quality production-level or prototype ceramic components ensures you get your products on time to deliver to your end market. All of our services are always performed in accordance with our strict ISO 9001:2015 quality assurance standards. We are your choice for ceramics manufacturing reliability excellence.

SEMICONDUCTOR CERAMICS MANUFACTURING

For years, Applied Ceramics has been a top provider of high quality materials for the semiconductor industry. Manufacturers of semiconductor processing equipment select us for our flexibility, responsiveness, and expertise - 3 key attributes required to deliver machined ceramics on time. Applied Ceramics employs excellent high-quality advantages to you while helping you avoid the typical "giant company" headaches associated with semiconductor ceramics manufacturing.

BEST TURN-TIMES & QUALITY IN THE LONG RUN

Ready for volume production? No need to wait months for product deliveries. Applied Ceramics delivers finished components with unparalleled speed without delays related to price quotes, raw material production, cumbersome ordering, and manufacturing protocols. Why do we have the industry's shortest lead time? Simple: We have the largest ceramics machining capacity on the West Coast. We keep an extensive array of pre-formed materials in stock and have a Class 100 Ultra Clean room for cleaning and packaging UHV components.